brinell hardness test theory|brinell hardness testing machine diagram : member club The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

web1 de mar. de 2018 · Скачать Grand Theft Auto III v1.9 APK (Мод: много денег) на андроид бесплатно. Взломанная версия на русском языке. 5play.org / Android / Игры .

{plog:ftitle_list}

WEBCNSport oversized tee. Brands. A-B. 100% Or Nothing Adapt Nutrition Alexanders Alpha Designs Alpha Lion Alpha Neon Applied Nutrition APS Nutrition Barebells Beast Pharm Boditronics Big Ben Big Boss Supplements Blackstone labs. C-L. Callowfit Chaos Crew CNP CNSport Conteh Sports Dark Labs DY Nutrition Gorilla Alpha Grenade High 5 HR .

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .

compression tester gauge bounces

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear .Brinell tests have long been the preferred method of assaying the hardness of metals during forming operations. The general significance of the test has been codified in empirical laws, .Brinell Hardness Test. Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings.

rockwell hardness tester procedure pdf

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with .The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

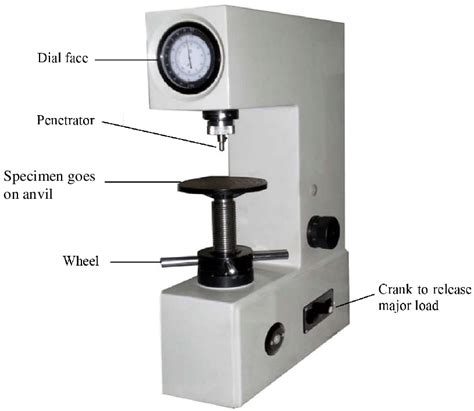

1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the .Brinell tests have long been the preferred method of assaying the hardness of metals during forming operations. The general significance of the test has been codified in empirical laws, .The hardness tester forces a small sphere, pyramid or cone into the surface of the metals by means of a known applied load, and the hardness number (Brinell or Vickers diamond .Brinell tests have long been the preferred method of assaying the hardness of metals during forming operations. The general significance of the test has been codified in empirical laws, especially those of Meyer, O’Neill and Tabor. On the other hand, the .

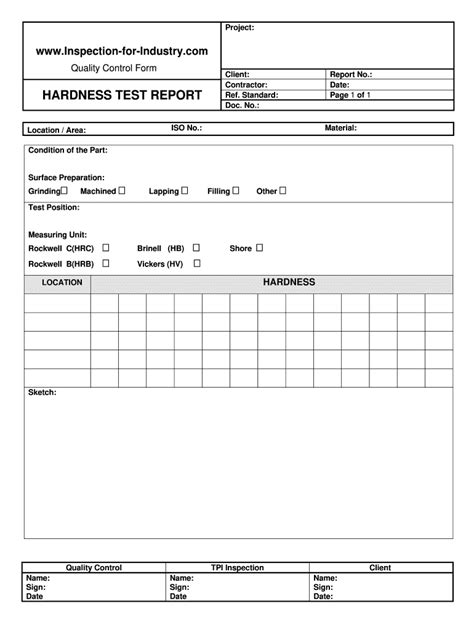

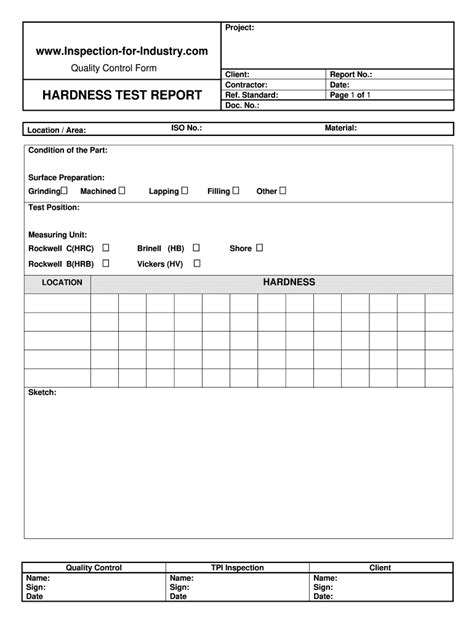

hardness tester lab report pdf

hardness test lab report pdf

2. BRINELL HARDNESS TEST I. AIM: To determine the Brinell hardness of the given test specimen. II. APPARATUS: Brinell hardness machine, test specimen. Brinell Microscope III. THEORY: INDENTATION HARDNESS- A number related to the area or to the depth of the impression made by an indenter or fixed geometry under a known fixed load.

Theory Procedure Self Evaluation Simulation Assignment Quiz Videos References Feedback . Brinell Hardness Test. Aim Theory Procedure .

The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages.

9. ROCKWELL SCALE The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test determines the hardness by measuring the depth of penetration of an indenter under a large load compared to the penetration made by a preload. There are different scales, denoted by a single letter, that use different loads or .The document describes a student experiment to perform a Brinell hardness test on a steel sample. The objectives were to examine how a metal deforms under different loads and to determine the Brinell hardness number. The procedure involved applying a 30 kg load with a 2.5mm diameter ball indenter to the steel sample for 30 seconds. Under the microscope, the .brinell hardness test uses and indenter that is|brinell hardness test theory : commercial The Brinell hardness test is used to measure and inspect materials with rough surfaces such as forgings and casting because you cannot use other methods to inspect them. . Brinell hardness test Theory related to Brinell hardness The first widely accepted and standardized indentation test, was proposed by J.A. Brinell in 1900. Brinell hardness test is mostly regarded as destructive test. This test is widely used in different industries. Brinell hardness test is macro hardness test in which large volume is .

The data obtained by Brinell hardness test with the tungsten carbide ball “HBW” and non – standardized hardened steel ball “HBS” measured by 8 appraisers were compared by Youden plot, MSA, analysis of uncertainty, t-test and analysis of variance (ANOVA). . THEORY BEHIND THE EXPERIMENT. Hardness is the property of a material (metal .The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures. . Theory and Principle of Brinell Test.

Brinell hardness testing is particularly suitable for thicker, heterogeneous materials in the low to medium hardness range! Thin sheets cannot be tested with the Brinell hardness test! The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material.The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.

The Rockwell hardness test is a indentation hardness test in which a diamond cone having an included angle of 120o and radius of curvature at the tip of 0.2mm, or a hardened steel or hard metal ball having a diameter of 1.5875mm for B, F, G and all 'T' scales or 3.175 mm for E, H and K scales are used.The indenter is forced into the surface of a test piece in two steps, initially a .The Brinell scale characterizes the indentation hardness of materials through the scale penetration of an indenter, loaded on a material test-piece. Tinius Olsen has many types of hardness testers available that can rapidly and accurately determine the hardness value of a wide variety of materials including metals, plastics, large parts and . The relationship between material Brinell hardness and material stress–strain behaviors has been extensively studied. Both ISO/TR 10108 and GB/T 1172-1999 (Chinese national standard) have elaborated a conversion of hardness values and tensile strength values for steel [1], [2].In 2007, Janosec used the same strip steel as the measured material both in a .

Brinell hardness tester series. Electronic Brinell hardness tester; Digital Brinell hardness tester (touch screen) Visual Brinell hardness tester (touch screen) Fully automatic Brinell hardness tester; Brinell hardness image processing system; Vickers hardness tester series.

brinell hardness testing machine diagram

3. Comparison of theoretical and measured lip heights. Sphere indentation with application to the Brinell hardness test 81 50I Theory c/D=0014 D=IOmm .Prestroined specimen c/D=0016 IOI ,Annealed specimen clD = 0014 Original surface 0 I 2 Distance from sphere-surface intercept, mm FIG. 4.Theory:- Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. In brinell testing machine the load is applied by a lever mounted on knife edges and carrying a hanger for suspendingThe Enigmatic Realm of Brinell Hardness Test Lab Report Theory: Unleashing the Language is Inner Magic In a fast-paced digital era where connections and knowledge intertwine, the enigmatic realm of language reveals its inherent Our store provides a variety of Brinell Hardness Test Lab Report Theory in different styles, including physical and electronic books and audiobooks. We supply tailored book recommendations based upon your passions and past analysis experiences. Join our community of Brinell Hardness Test Lab Report Theory book lovers to link with like-minded .

HARDNESS TESTING THEORY. Hardness is usually defined as the resistance of a material to plastic penetration of its surface. There are three main types of tests used to determine hardness: . BRINELL HARDNESS TEST: This test consists of applying a constant load, usually between 500 and 3000 kgf for a specified time (10 to 30 s) using a 5 or 10 .

Explanation: Brinell hardness test uses ball indenter. Its diameter is kept 1 mm for lower load 1 kgf. It is taken 10 mm for 500 kgf load. 7. Brinell hardness number is not a function of _____ a) Ball diameter b) Impression diameter . Dislocation Theory.The Brinell hardness number is defined as the ratio of test load to the surface area of indentation. Where, P = Load in Kg HBW = Brinell hardness number (Kg/mm 2 ) D = Diameter of the ball (mm) d = Diameter of the indentation (mm) Where, Constant = 0.102 = 1/(g ) = 1/9.81 g = acceleration due to gravity F = Force in Newton While testing, the indentation should not be . Applications of Brinell Hardness Test: The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the hardness of light metals like lead and tin, also hard metals like steel and iron. Conclusion:

This application training course is designed for beginners in hardness testing, laboratory assistants, quality inspectors, testing laboratory managers and planners, as well as machine operators. The training is conducted by proven specialists in hardness testing from Latzke, the ZwickRoell Group’s competence center for hardness testing.

brinell hardness testing charts

webBem vindo a Billion Slot 777 a nova plataforma de jogos on line. Cadastre-se na Billionslot 777 e venha se divertir. Ganhe premio de cadastro após a recarga na billionslot777 e a aos convite. Atendimento 24h on line.

brinell hardness test theory|brinell hardness testing machine diagram